Graphite Electrodes

Graphite electrodes are widely used in electric arc furnaces for smelting of steel, alloy steel, various alloys and nonmetals, Graphite electrodes supplied by GES always met the requirements of customers with their excellent qualities. Graphite electrodes are used in electric arc furnace and ladle furnace for steel making.

Our factories has owned advanced producing technology, high technical force and perfect testing methods. With different types of nipples, our plant can produce male and female electrodes. Most of our electrodes exported to USA, UK, Germany, Belgium, France, Japan, South Korea, India, Middle East and Russia

The electrodes we supply are as below

1. Regular Power (RP Grade)

2. Regular Power Impregnated (RPI Grade)

3. High Power (HP Grade)

4. Super High Power (SHP Grade)

5. Ultra High Power Grade (UHP Grade)

| Specifications | Unit of Measure | 76 mm – 256 mm Dia. Premium | 309 mm 610 mm Dia. Premium | 300 – 457 mm Dia. Premium | 457 – 610 mm Dia. UHP | 1205-1397mm High Powered |

| Ash (Max.) | % | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Apparent Density | g/cm3 | 1.58 – 1.68 | 1.58 – 1.68 | 1.60 – 1.76 | 1.60 – 1.72 | 1.68 – 1.75 |

| Porosity | % | 24 – 30 | 24 – 30 | 20 – 28 | 22 – 28 | 20 – 25 |

| Transverse | MPa | 11.7 – 18.6 | 7.9 – 13.7 | 9.7 – 14.8 | 9.0- 13.8 | 6.9 – 10.3 |

| Young’s Modulus | Gpa | ≤ 9.3 | ≤ 12.0 | ≤ 14.0 | ≤ 14.0 | ≤ 15.0 |

| Electrical Resistance | µΩm | 8.5 – 9.0 | 5.6 – 6.0 | 5.5 – 6.0 | 5.0 – 5.4 | 4.8 – 5.5 |

| Coefficient of Thermal Expansion | 10,-6 / °C | ≤ 2.9 | ≤ 2.4 | ≤ 2.0 | ≤ 1.5 | ≤ 1.5 |

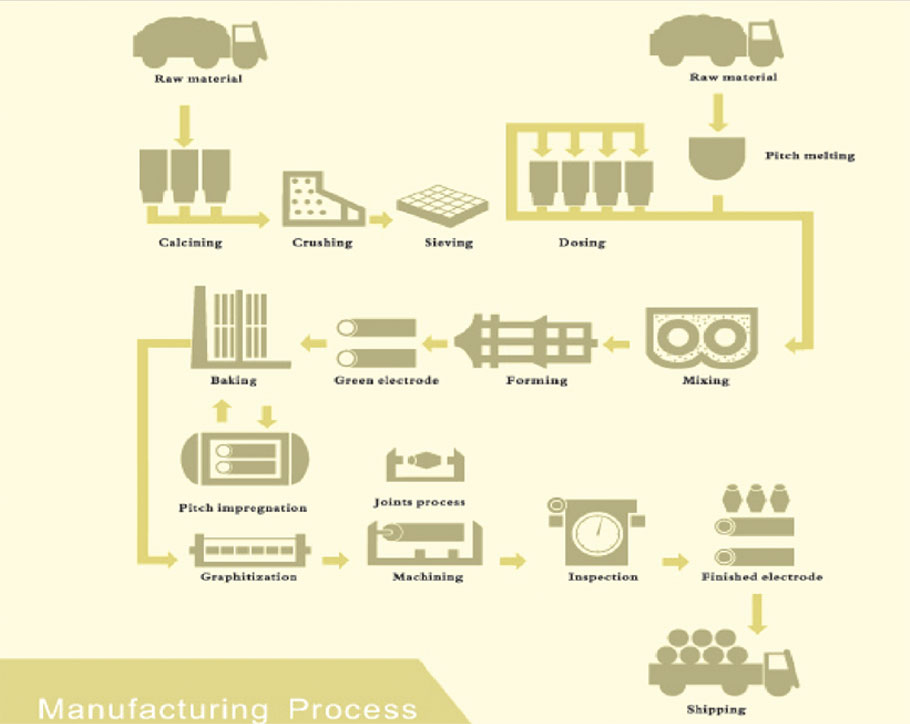

Manufacturing Process Of Graphite Electrodes

(From Calcining, Crusghing, Sieving, Graphitization, Machining, Inspection – Shipping)