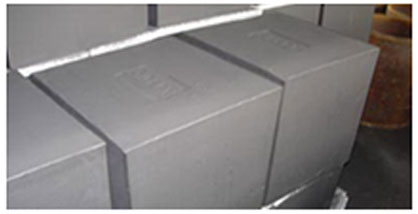

ISO-Static Graphite

Isostatic graphite is a carbon material with unique physical properties. It is produced by liquid Hot Isostatic Pressing (HIP) with the use of the special powder. HIP is used to convert powder in the solid state to fully dense components, resulting in better physical properties than those achieved by traditional melting or press and sinter manufacturing technologies. HIP is a forming and densification process, using heated gas under very high pressure. Unlike mechanical force which compresses a work piece from one or two sides, isostatic pressure is applied uniformly on all sides eliminating porosity without changing its net shape.

Raw Material: High quality petroleum coke or Pitch Coke or The Mixture and Coal Tar Pitch.

Forming Method: Hot Isostatic Pressing (HIP)

Process: Raw Material > Crushing > Screening > Dosing > Kneading > Iso-pressing > Baking > Impregnation > Re.baking > Graphitization > Machining > Inspection > Packing

Finished Products and Standard Sizes in mm:

o Blocks 400x400x400(500; 600)

o Blocks 1000x500x30; 1300x620x700

o Blocks 1950x480x400; 1220x500x320

o Rounds Dia400x450(500); Dia560x500

o Rounds Dia590x600; Dia680x650

o Rounds Dia750x650; Dia810x700

Main Applications:

o Solar Energy Application

o Electronic Items

o Photovoltaic

o Electric Discharge Machine (EDM)

o Continuous Casting

o Sintering and Die Casting Mold

o LED’s and Semi-Conductors

o Glass Industry and Chemicals